Transform Your Team into Lean Leaders.

For managers and leaders looking to drive measurable business improvements, enhance your skills with Lean Green Belt certification.

This course provides solutions and tools that will boost your confidence in implementing Lean practices in your organisation.

LBS Partners Green Belt Course

OVERVIEW

This Lean Green Belt training course equips participants with practical skills in Lean & Six Sigma methodologies. It focuses you on improving processes, reducing waste, and enhancing quality. You will learn key tools like root cause analysis, value stream mapping, and the most used problem-solving tools.

The course blends theory with real-world applications, preparing individuals to:

- Lead improvement projects

- Support Black Belts

- Contribute to operational efficiency in manufacturing, healthcare, services, and other industries.

DELIVERY

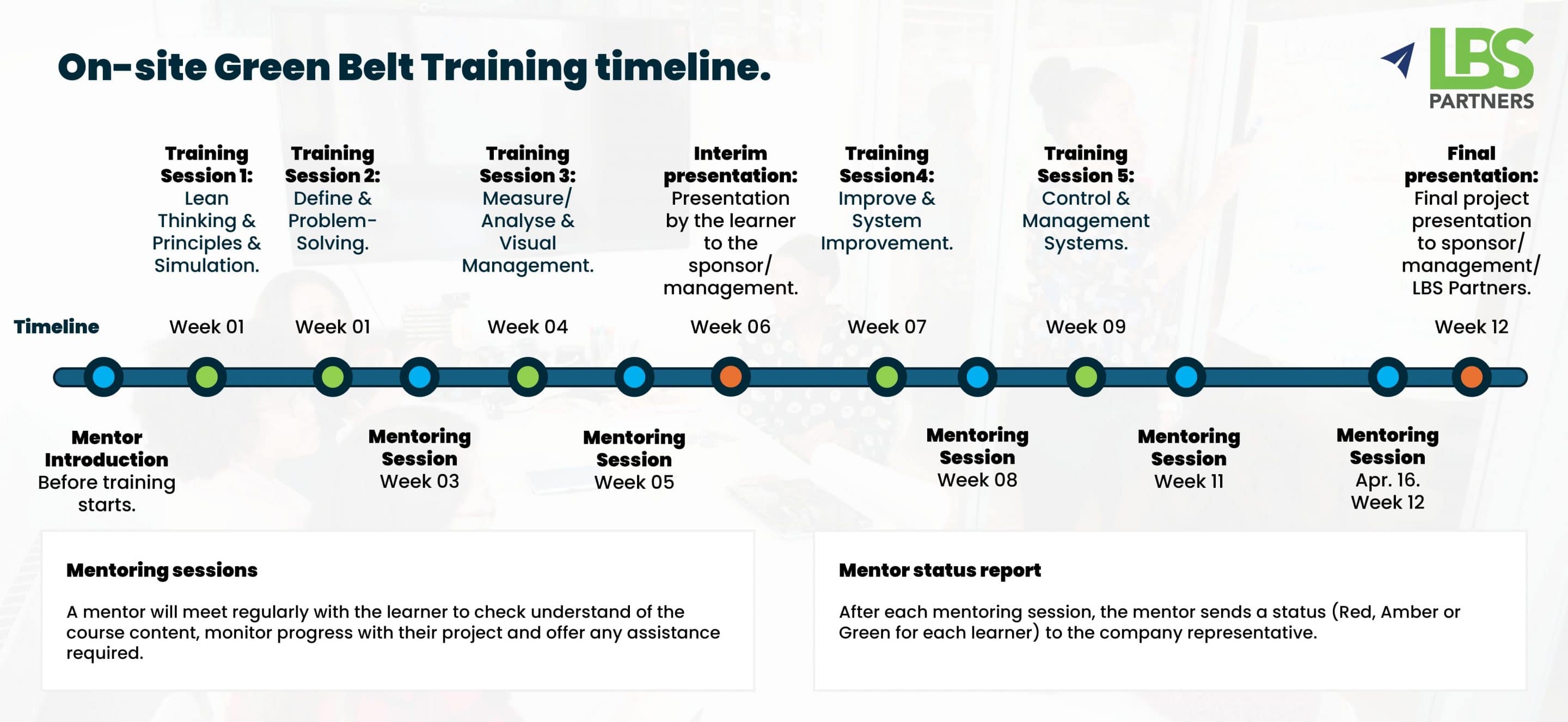

The Lean Green Belt Training is available both on-site and online, spanning 5 days on-site or 10 half-days online.

The delivery of the course is designed to accommodate your needs while leveraging modern technology for seamless learning.

As part of the course, you will complete an in-company project, employing the Lean methods taught on the course to fix a problem that directly affects you

You will be assigned a mentor who will help you with your understanding of the course and the implementation of your project.

OUTCOMES

You will learn the key concepts of Lean Thinking: Value, Value Stream, Flow, Pull, Perfection

Lean tools and techniques:

- Value Stream Mapping

- Kaizen

- Lean Six Sigma Green Belt concepts

Problem-solving methods:

- DMAIC framework

- A3 Methodology

COURSE TIMELINE & DETAILS

TRAINING

This Lean Green Belt training course equips participants with practical skills in Lean & Six Sigma methodologies. It focuses them on improving processes, reducing waste, and enhancing quality.

As part of the course, learners complete an in-company project, employing the Lean methods taught on the course to fix a problem that directly affects them.

MENTORING

Participants on the Green Belt course are assigned a mentor to assist them with their understanding of the course and the implementation of their project.

Mentoring enhances learning by providing personalised guidance, real-world insights, and support in applying Lean principles. Mentors help trainees navigate challenges, ensuring practical understanding and long-term retention of Lean methodologies.

TESTIMONIALS

CASE STUDIES

MANUFACTURING CASE STUDY:

CHALLENGES:

The number of customer complaints for a product increased by 240% between 2023 and 2024.

SOLUTION:

Problem-solving tools such as process mapping, Fishbone analysis and Cause Screening were used in root Cause Analysis.

- Enhancements were made to:

- Material storage methods

- Cleaning procedures

- Re-training in Good Manufacturing Practice.

OUTCOMES:

84%

REDUCTION IN CUSTOMER COMPLAINTS

€871,900

Annualised Savings

CASE STUDIES

MANUFACTURING CASE STUDY:

CHALLENGES:

Defects due to foreign matter in the product causes rework, scrap and time lost to production.

SOLUTION:

Employing the standard problem-solving tools, the root cause was identified and measures put in place. Improvements were made to:

- the layout of the area,

- the equipment in the area,

- work instructions for the job,

- training with operators

- audits were put in place.

OUTCOMES:

€23,000

COST SAVINGS

PRODUCTION TIME SAVED

CASE STUDIES

MANUFACTURING CASE STUDY:

CHALLENGES:

Throughput in the packout cell consistently fails to meet the plan.

SOLUTION:

Employing problem-solving tools such as:

- job work analysis,

- process mapping,

- motion mapping and

- root cause analysis

Improvements were made to:

- work methods,

- batch size reduction and

- changes to the area layout.

OUTCOMES:

€25,000

COST SAVINGS

waste of motion was reduced

COURSE DELIVERY

11 Half Days Online

1 Day Mentoring

Per Particpant

5 1/2 Full Days Onsite

1 Day Mentoring

Per Particpant

Our Lean Trainers

NIALL TUITE

Lean Consultant & Director

EDDIE O'NEILL

Lean Trainer

EDDIE MCNALLY

Lean Consultant